Minyue Technology - robot intelligent application expert, focusing on laser vision system and industrial robot offline programming software products

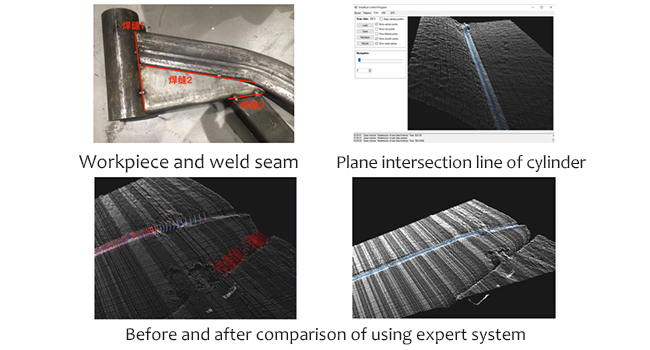

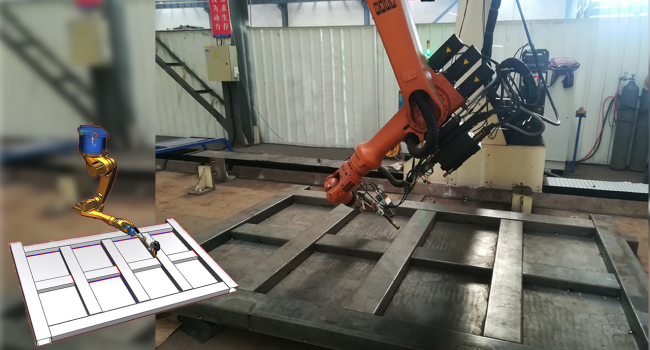

Standard industrial robot welding is efficient and flexible, but it can only move along a fixed path according to the program written in advance. In mass production, due to the workpiece size error, thermal deformation in welding process, tooling instability and other factors, it will lead to weld track and weld characteristics are conform to actual welding parameters and thereby reducing the welding quality or even leading to welding failure.

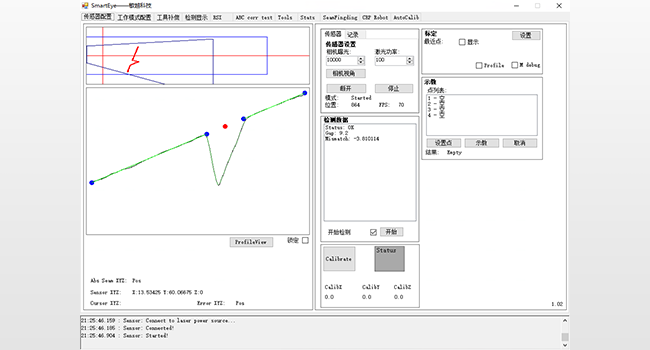

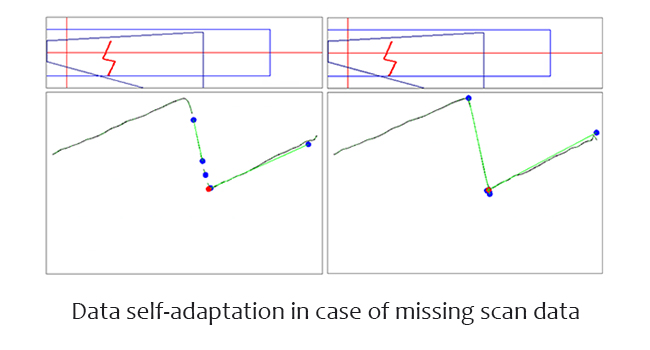

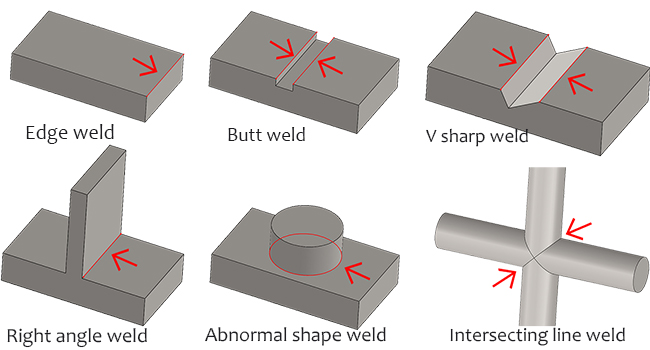

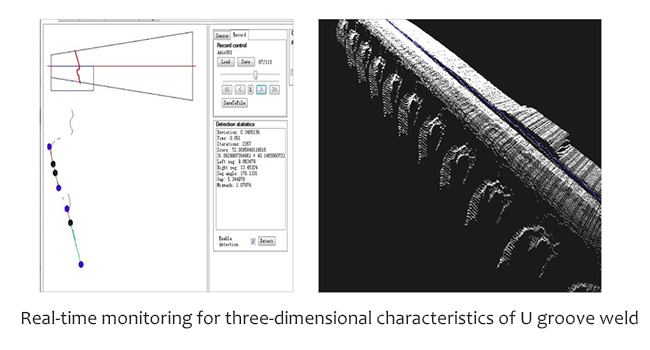

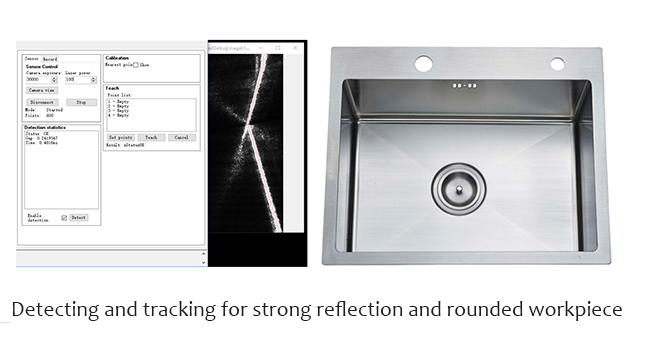

SmartEye series of 3D laser seam tracking system developed by Minyue Technology can detect the position and characteristics of welding seam in real time, control and guide robot movement, real-time error compensation for the pre-programmed path, and reduce repair welding rate. At the same time, the welding process parameters can be modified according to the characteristics of the weld, thus improve the welding quality of industrial robots. The sensor can eliminate the positioning error and the adverse effects caused by thermal deformation, reduce the cost of fixture in the welding process, and improve the flexibility level of the welding workstation. It has been widely used in automobile manufacturing, shipbuilding, high-speed train, tricycle, tank welding and other welding fields.