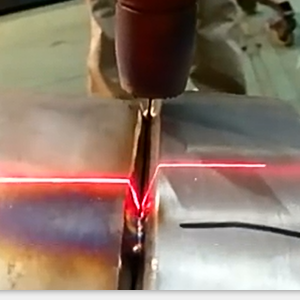

激光焊缝跟踪

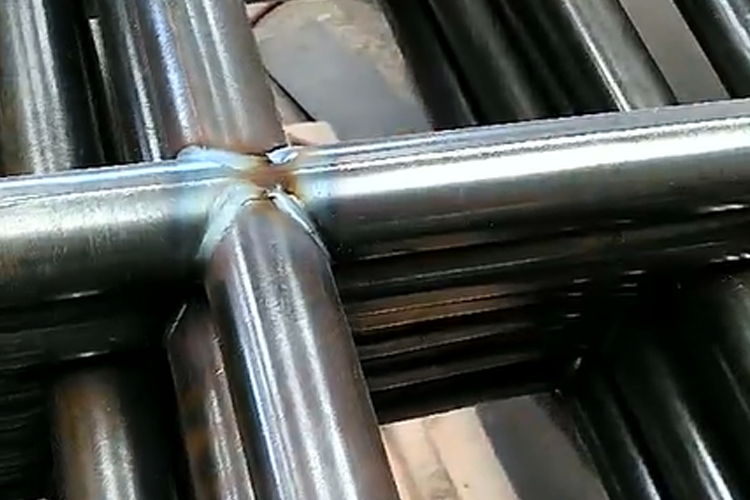

支持国产进口机器人品牌,支持多层多道,摆动焊接跟踪,结合敏越科技激光视觉系统-自定义焊接工艺库,神经网络等技术,实现闭环焊接,有效应对工程机械行业-焊缝宽、坡口深、且工件一致性不好的特点。

【华东】王工:18751664051 【华中】夏工:18511589958 【华北】钊工:18552907035 【西南】付工:15902859219 【东北】孙工:15862217721

地址: 北京,南京,佛山

敏越科技针对多品种,小批量的厚板坡口切割应用,遇到编程繁琐、定位不准等问题,为客户提供免示教、智能化、易用的解决方案。

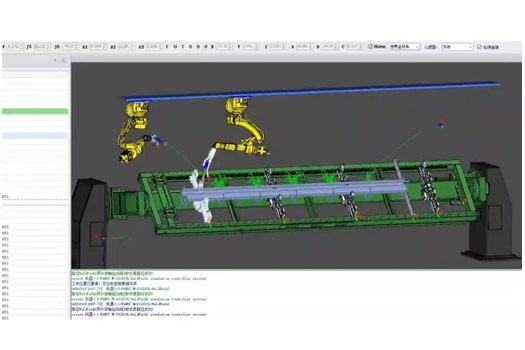

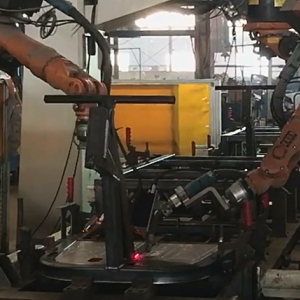

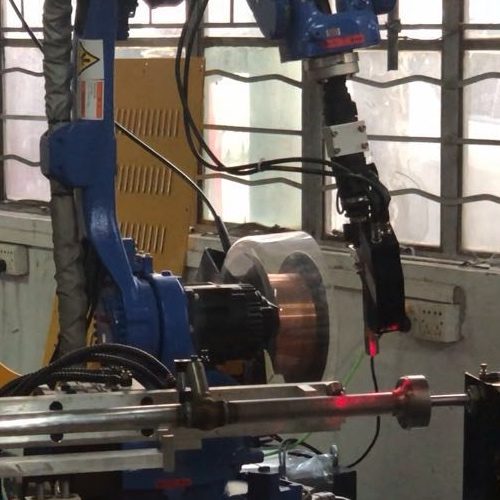

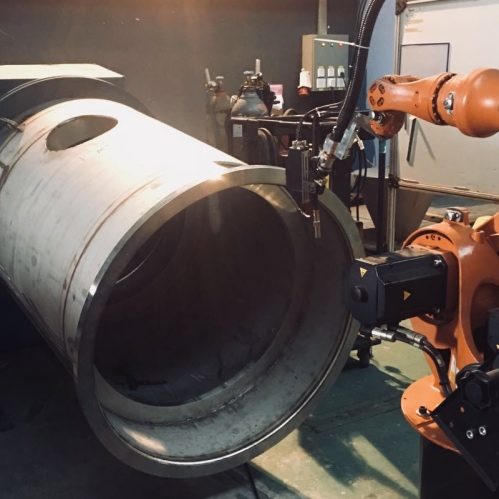

敏越科技智能焊接系统,激光视觉焊缝跟踪系统,实现机器人免示教编程焊接,形成高效率、高精度、适用范围广、可靠性强的机器人标准化生产单元。

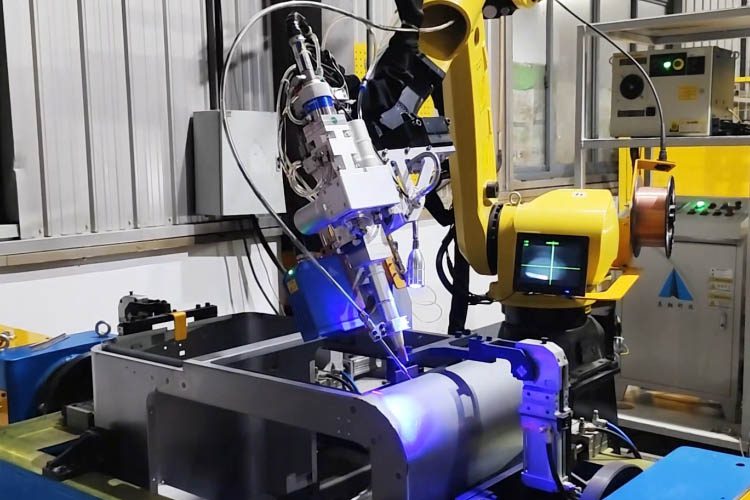

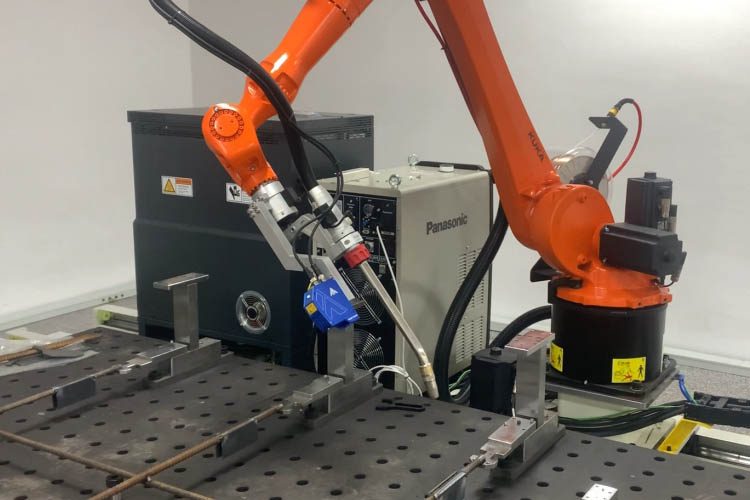

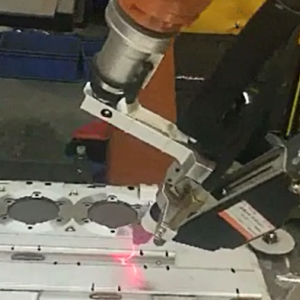

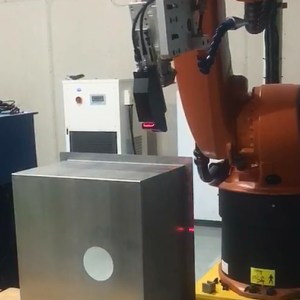

敏越科技为客户提供智能化定制焊接解决方案,激光焊缝跟踪系统, 通过机器视觉、人工智能等技术,赋予传统焊接设备“眼睛”与“大脑”,为客户提供高效率、柔性、稳定的焊接加工方式, 帮助企业跨入智能制造时代。

智能免示教焊接系统,兼容KUKA、FANUC、ABB、安川四大家族机器人以新松,纳博特等国产机器人,配合敏越科技自主研发的激光焊缝跟踪系统SmartEye+RobotSmart…

Smartcut 智能坡口切割工作站,产品依托敏越在CAD/ CAM、机器人学和3D视觉、人工智能等方面的多年积累,在敏越已有的自研成熱的智能决策系统RobotSmart和3D视觉传感器的基础上…

希望您选择敏越,选择信任。期待与您合作!

敏越科技让机器更智能!

种类繁多工艺复杂

激光点寻位焊接

支持阴角、阳角连续切割

布局效率高

实时跟踪、降低能效

定位精度高、布局难度小

高压电设备,段续亚弧焊

激光焊接,水槽焊接

短焊缝密集,气保焊

高反射,相贯线焊接

三通管道焊接

圆管,螺旋管焊接

期待您的加入!