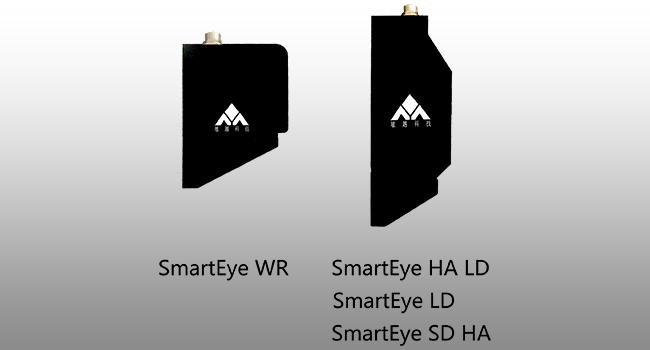

Minyue Technology - robot intelligent application expert, focusing on laser vision system and industrial robot offline programming software products

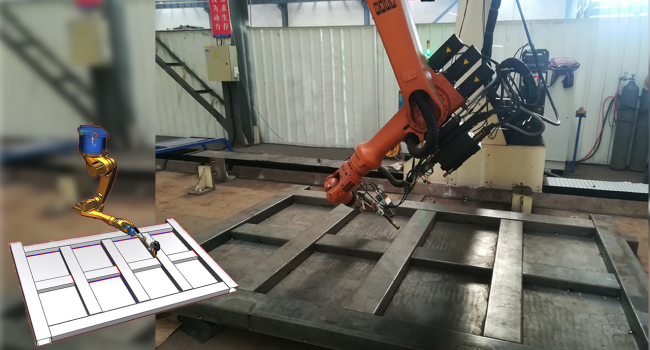

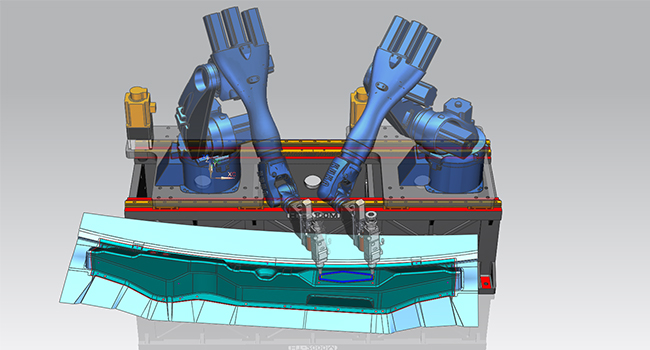

敏越科技智能焊接系统,主要由敏越科技激光焊缝跟踪系统、敏越科技离线编程软件,3D视觉扫描系统和机器人智能焊接等先进技术构成,实现机器人免示教编程焊接,形成高效率、高精度、适用范围广、可靠性强的机器人标准化生产单元。